Recruiting the right talent in the manufacturing industry is more complex than ever. With evolving technologies, rising skill gaps, strict compliance standards, and high turnover rates, companies can no longer afford to rely on outdated or ad-hoc hiring methods. One wrong hire can lead to delayed production, costly errors, and increased safety risks. That’s why a structured, strategic recruitment approach is essential—especially in a field where precision, performance, and reliability matter.

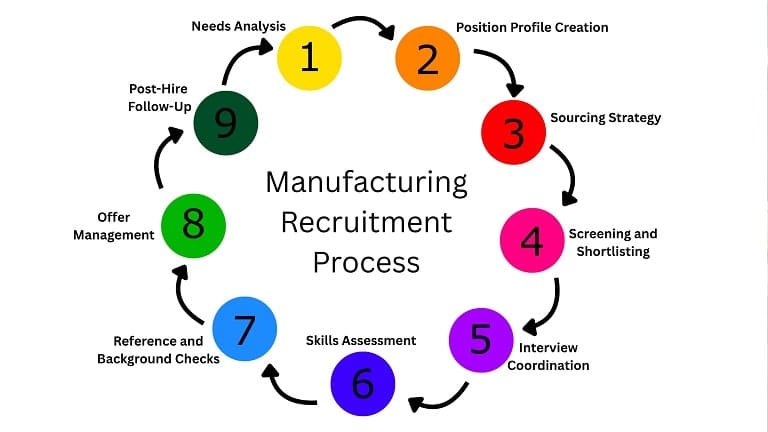

At our firm, we understand these challenges firsthand. That’s why we’ve developed a comprehensive 9-step manufacturing recruitment process—a productized, transparent, and repeatable system designed to deliver consistent hiring success. Rather than simply filling positions, our process ensures every candidate is a true match for the role, both technically and culturally.

From the initial needs analysis to post-hire follow-ups, each step is designed to reduce risk, improve retention, and align hiring with your business goals. This isn’t just recruitment—it’s a service product that adds real value to your operations.

In this article, we’ll walk you through our entire process, showcase what makes it different, and share real-world results from clients who have benefited. If you’re looking to hire smarter and build stronger teams, this is the process you can trust.

Why a Structured Manufacturing Recruitment Process Matters

Hiring in the manufacturing industry isn’t just about filling positions—it’s about finding individuals who can meet technical demands, maintain productivity, and ensure safety and efficiency on the shop floor. Yet, many companies still rely on informal or inconsistent hiring practices, which often lead to poor fit, high turnover, and costly mistakes. These traditional methods lack clarity, rely heavily on instinct, and often skip important steps like thorough screening or cultural alignment.

Manufacturing roles come with unique challenges. Whether it’s operating heavy machinery, maintaining safety protocols, meeting production quotas, or managing shift-based operations, the stakes are high. A bad hire can result in delays, compliance issues, or even workplace accidents. That’s why a structured recruitment process is not just a best practice—it’s a necessity.

A well-defined, repeatable recruitment process brings clarity, consistency, and control. It ensures that every hire goes through the same rigorous evaluation—starting from a deep understanding of the role, to sourcing, screening, assessing skills, and following up post-hire. This method reduces guesswork and eliminates bias, ensuring the best candidate is selected based on data and fit—not assumptions.

Moreover, structured hiring significantly improves retention and ROI. When candidates are well-matched from the start, they onboard faster, perform better, and are more likely to stay long-term. This reduces hiring and training costs, improves team morale, and enhances overall productivity. For HR teams and plant managers, it creates a predictable system that saves time and reduces hiring risks.

Ultimately, a structured manufacturing recruitment process is your competitive advantage. It signals professionalism, builds trust with candidates, and aligns hiring with broader business goals. In an industry where every hour counts and every role matters, this level of precision can make all the difference in building a resilient, high-performing workforce.

Our 9-Step Manufacturing Recruitment Process

At JRG Partners, we’ve refined manufacturing recruitment into a strategic, productized process that delivers consistent, high-quality results. Our 9-step method is designed to remove guesswork, reduce hiring time, and ensure a long-term fit—both culturally and technically. This structured approach is especially critical in manufacturing, where skill, safety, and reliability are non-negotiable.

Here’s a detailed breakdown of how our proven process works:

Step 1: Needs Analysis

We begin with a deep-dive consultation involving key decision-makers. This step allows us to understand the true purpose behind the hire—whether it’s to reduce downtime, drive efficiency, scale a production line, or fill a leadership gap.

We assess team dynamics, business goals, role criticality, production cycle pressures, and the cultural environment of your facility. The result is a fully informed recruitment roadmap tailored to your organization’s exact needs.

Step 2: Position Profile Creation

Going beyond a generic job description, we craft a detailed Position Profile. This includes role responsibilities, must-have and nice-to-have skills, required certifications, years of experience, safety qualifications, and tools/software proficiency.

We also define the performance metrics for success and potential career paths—creating a clear and compelling profile that attracts qualified, motivated candidates aligned with your expectations.

Step 3: Sourcing Strategy

Our sourcing strategy is built for both speed and precision. We utilize multiple channels—specialized job boards, LinkedIn, referrals, trade associations, internal talent databases, and passive candidate outreach.

We also engage niche talent pools specific to manufacturing roles, such as CNC operators, Six Sigma experts, and OSHA-certified technicians, to ensure we’re targeting the best—not just the most available—talent.

Step 4: Screening and Shortlisting

Every candidate goes through a multi-layered screening process. We review resumes for experience, qualifications, and alignment with the Position Profile. Next, we conduct structured pre-screening calls to assess communication skills, technical depth, shift availability, and culture fit.

Only the top-tier candidates—who meet both role-specific and soft-skill requirements—are shortlisted and presented to you for further review.

Step 5: Interview Coordination

Our team takes the administrative burden off your plate. We handle interview scheduling across shifts or multiple locations, coordinate feedback across stakeholders, and ensure candidates are prepared and well-informed.

We also guide you in structuring your interview process (technical rounds, panel interviews, hands-on tests) to ensure consistency and fair evaluation across candidates.

Step 6: Skills Assessment (Optional)

When needed, we incorporate technical testing into the process. This may include machine-operation simulations, problem-solving assessments, safety protocols, or software usage (like AutoCAD or ERP systems).

We can use our in-house tools or customize tests based on your requirements—ensuring you get validated, job-ready talent.

Step 7: Reference and Background Checks

Before extending an offer, we thoroughly verify candidate credentials. This includes:

Speaking with former supervisors to assess performance and reliability

Validating employment history and certifications

Running criminal and safety background checks, especially critical for manufacturing environments that demand compliance and operational trust

Step 8: Offer Management

We act as the bridge between you and the candidate during this crucial stage. We present and negotiate offers on your behalf, ensuring all expectations (compensation, job duties, location, benefits, onboarding timeline) are crystal clear.

Our proactive communication helps reduce offer rejections, no-shows, and last-minute changes—securing a smooth transition from acceptance to onboarding.

Step 9: Post-Hire Follow-Up

Our commitment doesn’t end on Day One. We check in with both you and the new hire at 1 week, 30 days, and 90 days to ensure mutual satisfaction.

If challenges arise during the onboarding period, we step in to support both sides and ensure retention. These follow-ups help us refine future searches and strengthen long-term relationships with both clients and candidates.

Our structured recruitment process doesn’t just fill a vacancy—it builds workforce stability, operational reliability, and long-term growth for your manufacturing business.

Ready to learn more about how we support leadership and technical hiring across the manufacturing industry? Visit our Manufacturing Executive Recruiters service page.

What Sets Our Manufacturing Recruitment Process Apart

In a sector as specialized and high-stakes as manufacturing, a one-size-fits-all recruitment approach simply doesn’t work. That’s why we’ve developed a productized, transparent, and repeatable recruitment process that sets us apart from traditional agencies. Instead of relying on intuition or fragmented methods, we follow a consistent 9-step system that delivers predictable, high-quality results every time.

Our recruitment process has been carefully designed to function like a product, with clear stages, measurable outcomes, and built-in checkpoints. This not only improves efficiency and accuracy but also builds trust with our clients. You always know what’s happening, why it’s happening, and what comes next—eliminating the uncertainty that often comes with hiring.

What truly distinguishes our service is our team of specialized recruiters with deep industry expertise. They understand the unique technical and cultural demands of manufacturing environments—from CNC machinists and line supervisors to production managers and safety officers. Their knowledge allows them to ask the right questions, screen for the right skills, and make faster, more accurate placements.

We also believe in continuous improvement. Our process includes built-in feedback loops after every critical stage—from client intake to post-placement check-ins. This allows us to adapt our strategy in real time, identify what’s working, and refine what’s not. The result is a smarter, more agile recruitment process that evolves with your needs.

Most importantly, our clients stay with us. We’ve earned a reputation for delivering not just candidates, but lasting hiring outcomes. Our high retention rates and repeat business are a reflection of the trust we’ve built and the results we consistently deliver.

In short, what sets us apart is not just what we do—but how we do it. With a structured, transparent, and industry-focused approach, we don’t just fill jobs—we help you build a stronger, more reliable manufacturing workforce.

Real Results: Case Studies or Testimonials

The strength of any recruitment process lies in its outcomes—and our 9-step manufacturing recruitment process has consistently delivered measurable success for our clients across various manufacturing sectors. From reducing hiring time and turnover to improving workforce productivity and retention, our structured approach brings real value to every hire. Below are a few case studies and testimonials that demonstrate how our productized recruitment model translates into real-world impact.

Case Study 1: Reduced Time-to-Hire by 40%

A precision engineering firm was struggling to hire experienced CNC machinists, leading to production delays and lost revenue. After partnering with us, we implemented our full 9-step process, starting with a deep needs analysis and ending with post-hire follow-ups. We filled three critical positions within four weeks—a 40% reduction in their typical hiring time. The client reported improved shop floor efficiency and reduced overtime within the first month.

“Your team didn’t just find us candidates—they found the right people, quickly and professionally. This process changed the way we approach hiring.”

— Operations Manager, Engineering Firm

Case Study 2: Lower Turnover, Better Culture Fit

A packaging manufacturer had a high turnover rate in their production supervisor roles, mostly due to misaligned expectations and unclear job definitions. We helped redefine their position profiles and introduced behavior-based screening and assessments. Within 60 days, we placed two supervisors who have now been with the company for over 18 months.

“We used to treat hiring as a checkbox activity. Your structured process helped us rethink everything. We now have leaders who truly fit in.”

— HR Head, FMCG Manufacturing Company

Case Study 3: Built a Leadership Pipeline

A large automotive components manufacturer needed to fill multiple mid-level management roles quickly as part of an expansion plan. Using our end-to-end process, we hired five managers across three locations in less than 8 weeks.

“We gained not just employees, but future leaders. The clarity, transparency, and follow-through of your process are unmatched.”

— Plant Director, Automotive Supplier

These examples highlight what sets our recruitment service apart: real results, real relationships, and long-term impact. We don’t just fill vacancies—we help build stronger, more resilient manufacturing teams.

Frequently Asked Questions (FAQ)

What makes your 9-step manufacturing recruitment process unique?

Our process is fully productized—meaning it’s standardized, repeatable, and transparent. Unlike traditional recruitment, each step is fine-tuned for manufacturing roles, with built-in quality control, cultural alignment checks, and post-hire support to ensure a long-term fit.

How long does your typical manufacturing recruitment process take?

Depending on the role complexity and availability of candidates, our placements typically take between 2 to 6 weeks. Urgent roles can be expedited thanks to our robust pipeline and industry connections.

What types of manufacturing roles do you recruit for?

We recruit for a wide range of roles—from frontline operators like CNC machinists and technicians to mid-level managers, plant supervisors, and C-suite executives such as Operations Directors and Plant Managers.

How do you ensure cultural fit in manufacturing hires?

We gather insights on your company’s work culture during the needs analysis stage and assess candidates through behavioral interviews, reference checks, and personality-based evaluations to ensure alignment beyond just technical skills.

What is the ROI of using a structured recruitment process?

Clients report faster time-to-hire, reduced turnover, and higher productivity. Our process reduces the cost of bad hires by ensuring that every placement contributes to long-term business goals and operational success.

Do you offer a guarantee on placements?

Yes, we stand behind our process. If a placement doesn’t work out within the agreed timeframe, we’ll find a replacement at no additional cost—demonstrating our confidence in delivering a perfect fit.

Conclusion

In a high-performance industry like manufacturing, every hire matters. Our 9-step recruitment process isn’t just a method—it’s a commitment to delivering quality, reliability, and results. From understanding your needs to post-hire support, each stage is thoughtfully designed to minimize risk and maximize fit.

What sets us apart is our deep industry expertise, transparent communication, and our productized approach that brings structure and predictability to hiring. The case studies and client testimonials speak for themselves: this process works.

If you’re ready to stop guessing and start hiring with precision, we invite you to partner with us. Let’s build a manufacturing team that drives long-term success—one perfect hire at a time. Explore how we support businesses across the industry on our Manufacturing Executive Recruiters service page.